Services

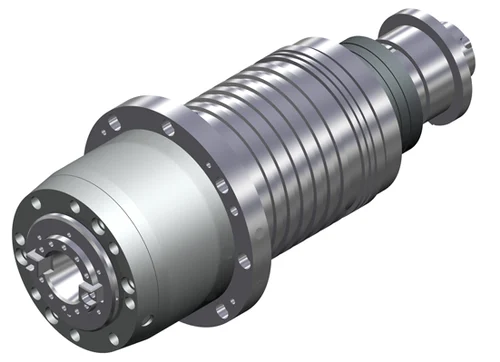

CNC Spindle Manufacturing

We specialize in designing and manufacturing CNC spindles for various applications,

including turning, milling, grinding, and special-purpose machines. Our spindles are

engineered with precision, ensuring high performance, reliability, and longevity. We

manufacture spindles to meet specific customer requirements, including:

Motorized CNC Spindles

Belt-driven CNC Spindles

Direct-drive Spindles

Multi-head Spindles

Spindle Reconditioning and Repair

We provide comprehensive reconditioning and repair services to extend the life and

efficiency of your spindles. Our team uses advanced diagnostic tools and cutting-edge

techniques to restore spindles to their original specifications. Services include:

Bearing replacement and alignment

Balancing and vibration analysis

Surface grinding and finishing

Performance testing and calibration.

Custom Spindle Solutions

Every manufacturing process is unique, and we understand the need for tailor-made spindle solutions. Our team works closely with customers to design and develop custom spindles that meet their specific operational and performance requirements.

Machining center spindles

At Akshara Micro Tech, we specialize in delivering high-performance Machine Centre Spindles designed to meet the precise demands of modern machining. Our spindles are engineered to enhance productivity, ensure superior surface finish, and provide unparalleled durability across various industrial applications.

Precision Components Manufacturing

In addition to spindles, we manufacture precision components such as:

Precision Lock Nuts

Collets and Collet Holders

Thread Plug and Ring Gauges

Plain Plug and Ring Gauges

Bearing Housings and Draw Bars

Testing and Quality Assurance

Quality is at the core of our operations. Our facility is equipped with advanced testing

equipment and high-precision measuring instruments to ensure that every spindle and

component meets stringent quality standards. Services include:

Ultrasonic and chemical analysis of raw materials

Performance testing for spindles under real-time conditions

Sub-zero, cryogenic, and nitriding processes for added durability

High-Capacity Manufacturing

With the capability to produce 400–500 spindles per month, we support the demands of industries worldwide. Our streamlined manufacturing process ensures timely delivery without compromising on quality.